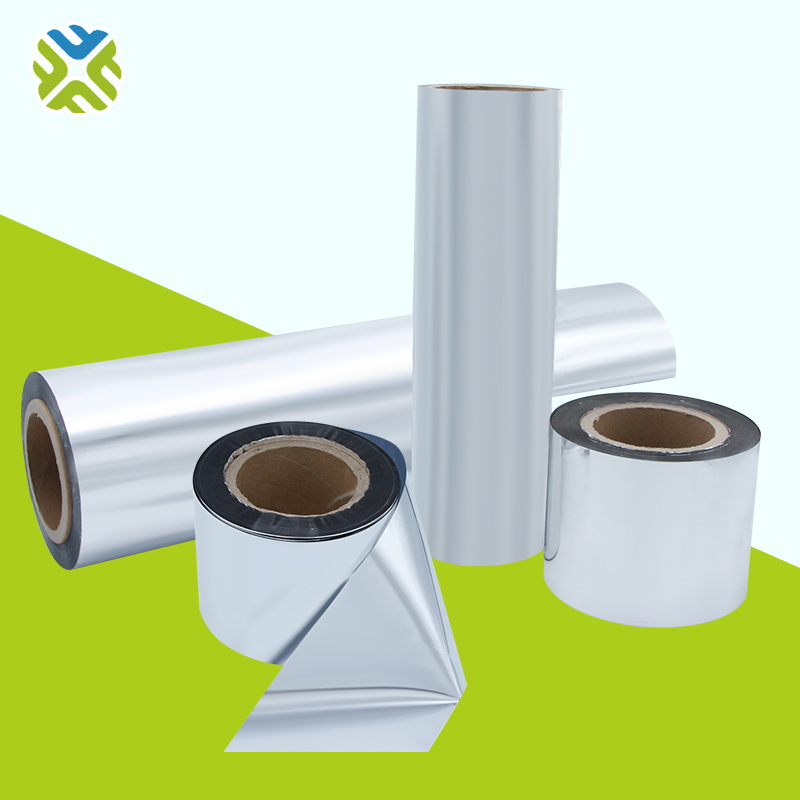

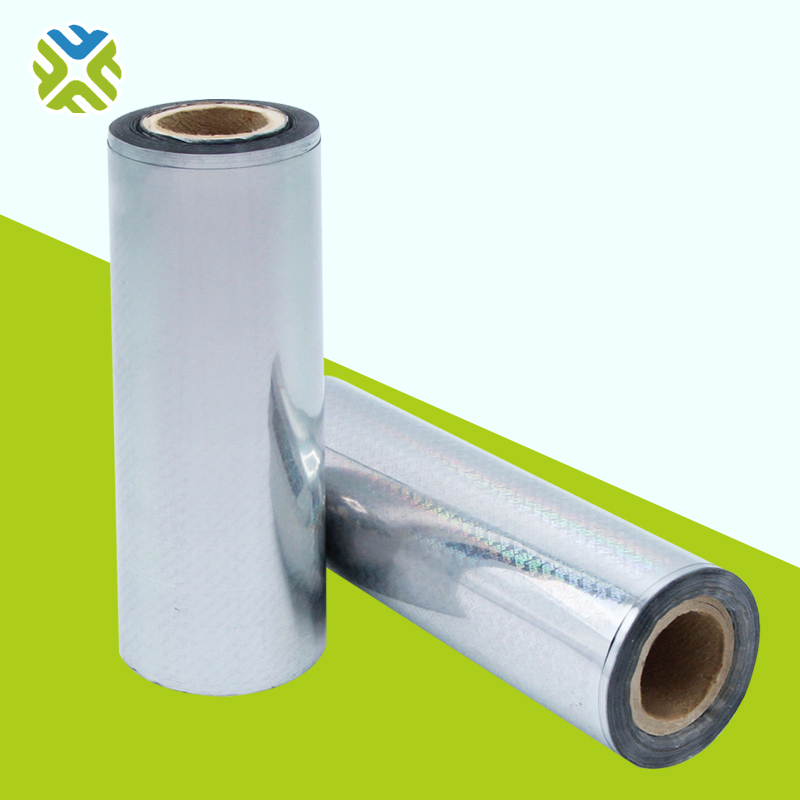

There are many molding methods for plastic film, such as calendering, casting, blow molding and stretching. Among them, biaxial stretching has become one of the most concerned methods in recent years.

The common characteristics of biaxially stretched films are high tensile strength, good straightness, high transparency, good high and low temperature resistance, good insulation performance, high barrier property, non-toxic and tasteless. It is very suitable for the packaging of food and high-end goods, and is also widely used in electronic industrial products. Photosensitive film, tape substrate, especially optical film, etc. are excellent materials.

After biaxial stretching > on-line antistatic coating, in addition to molecular outward, the microstructure of the film also has great changes, which makes its performance significantly different from that of the non stretched film:

(1) Mechanical properties.

The tensile strength and elastic modulus of the biaxially stretched film can be increased several times, and its impact strength is obviously different from that of the non stretched film for PP, PVC and pet. Especially at low temperature, its impact strength is not reduced, that is, its cold resistance is excellent, and its performance is not deteriorated at high temperature, which makes the use temperature range of the biaxially stretched film very wide.

(2) Thermal performance.

Heat shrinkability is the characteristic of biaxially stretched film, which can be used for shrink packaging. In order to make the film have low temperature shrinkage, it is particularly advantageous to use the tube film method of simultaneous biaxial stretching. This is because the microstructure can be increased under biaxial tension, and the film bubble is directly cooled and in a stretched state.

(3) Optical properties.

After biaxial stretching, the transparency and transparency of the film are improved. In particular, since the spherulite structure is not formed, the refractive index of the film is increased. Therefore, the gloss and transparency are not reduced due to friction.

(4) Electrical performance.

The breakdown voltage, volume resistivity and other electrical properties were improved in different degrees in the biaxially stretched films. Sometimes, electrostatic problems occur.

(5) Air tightness.

After biaxial stretching, the transmittance of water vapor, oxygen or other gases of the film produced by crystalline polymer is reduced by 1 / 3-1 / 2, which is particularly important in the food packaging industry.

(6) Antistatic property

After on-line coating with long-lasting polymer transparent conductive liquid, the surface of the product is uniformly coated with permanent antistatic coating, which directly acts on the surface, without affecting the transparency and the antistatic effect is more excellent!

Address:A2110, Tianrun Building, Dongfeng Street And Jinma Road, High-Tech Zone

Address:A2110, Tianrun Building, Dongfeng Street And Jinma Road, High-Tech Zone

Mobile:+8615169643109

Mobile:+8615169643109

Phone:+8615169643109

Phone:+8615169643109

Whatsapp:+8615169643109

Whatsapp:+8615169643109

Wechat:15169643109

Wechat:15169643109